The Drug Distribution rotation allowed an opportunity to familiarize myself with RJH, VGH and SPH, the differences in how the pharmacies work and how medication gets from the pharmacy to the patient once it has been ordered. Following the flow of medications through the hospitals lent me perspective into where the potential for medication errors may arise and the steps that can be taken to minimize the chance of this happening.

I was orientated to the Patient Safety & Learning System (PSLS) and I used this system to report a ‘near miss’ on the ward. Despite the many safety checks required between the time a medication is ordered to when it is administered, this patient had come close to receiving a discontinued medication. This experience reinforced the need to stay vigilant and to work together to improve patient safety.

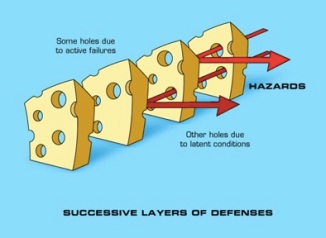

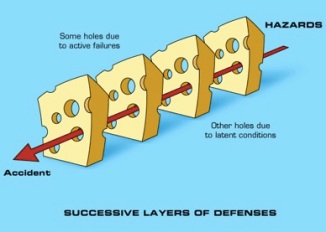

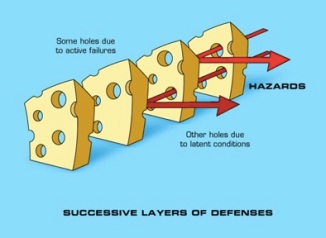

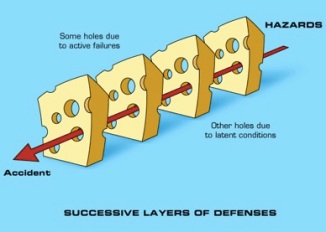

My favorite analogy of these safety checks came from a pharmacist on the ward. It is called the ‘Swiss Cheese’ model. Each layer of Swiss cheese represents a stage of the drug distribution system. Alone, there are many holes where medication errors may occur however when the layers are stacked together, these risks are mitigated. It is only where all the holes line up that medication errors reach the patient.

I was introduced to several computerized systems that aim to reduce the risk of human error, the holes in the Swiss cheese, including the Acudose Cabinet. This system for storing and distributing ward stock reduces the risk for medication errors. It does this from the point of drug delivery from the pharmacy, through barcoding, to when the nurse ‘removes’ a medication for use using a computer interface and patient specific parameters. We discussed the pros and cons of this system vs. manual ward stock as a group with Winnie and we will review the entire drug distribution cycle using each of these soon. Speaking of, I had better get back to my flow charts! There are many steps where medication errors may occur and therefore potential to identify and reduce these risks improving patient safety.

For those who find images helpful, especially when it involves delicious cheeses, this is an illustration of the “Anatomy of an Error.”

http://patientsafetyed.duhs.duke.edu/module_e/swiss_cheese.html